What is an oil-free air compressor? Many customers and friends outside the industry are not particularly clear. This issue of Gaoling oil-free scroll main engine will tell you what an oil-free air compressor is. I hope it will be helpful to you.

In 1969, Mr. B.zimmern (Xin Maien) of France invented a highly sealed and efficient oil-free screw compressor. Once this technology was discovered, it was used in military manufacturing and shipbuilding. This has enabled the rapid and mature development of oil-free screw compressor technology. Oil-free, but can be compressed normally, isn't this technology very good? Indeed, this technology is very good.

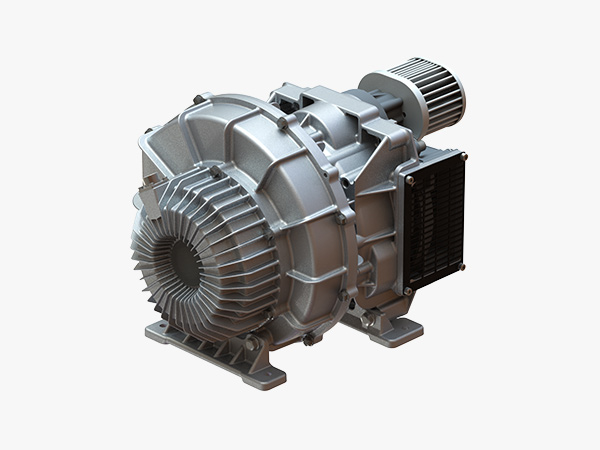

The dry oil-free screw is mainly a twin-screw compressor. There is no lubrication in the compression chamber, and there is only lubricating oil in the gearbox, which can be said to be dry. There is a gap between the rotors, and they do not contact each other. They have a synchronous gear structure, and the rotors rely on synchronous gears to transmit torque and positioning.

Both the male and female rotors at the inlet and exhaust ends have shaft seal structures to separate the medium gas and lubricating oil. The surface of the rotor has a special coating. Since there is no contact, the first compression pressure is not very high. To increase the pressure, two-stage compression is used.

Isothermal compression has a better compression effect. In fact, isothermal compression cannot be achieved, so there is an intercooler and a steam trap (cooling, drainage) after the first stage of compression, and there is also a rear cooler after the second stage of compression.

The pressure of the first stage of compression is about the square root of 2, and then this pressure enters the second stage of compression. The pressure discharged by the second stage of compression meets the system requirements, so the second stage compression ratio is higher, the working environment is more stringent, and the life is shorter than the first stage.

Due to the high speed and the high temperature inside the head, the head shell adopts a one-time lost mold technology for cooling. This head shell is completely separated from the rotor. The shell is generally cooled by oil.

Zhejiang Gaoling New Energy Technology Co., Ltd. is based on oil-free scroll technology and continuously develops, produces and promotes it. It has now formed five major product series, including oil-free scroll air compressors, oil-free and water-free scroll air compressors, oil-free scroll air compression nitrogen generators, high-altitude airborne oxygen generators, and new integrated inner and outer rotor brake steam pumps. Gaoling has now become one of the largest oil-free scroll compressor manufacturers in China.

400-880-5687 / 138 5725 7465

400-880-5687 / 138 5725 7465