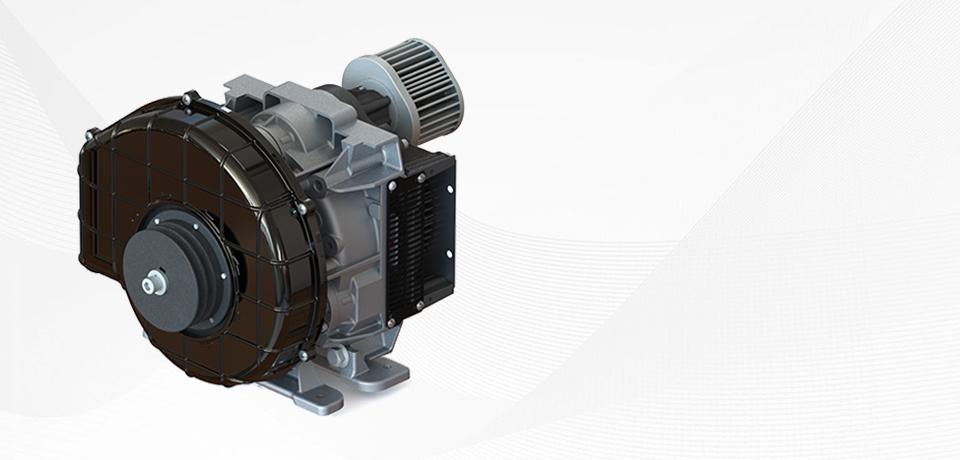

SCROLL AIR COMPRESSOR

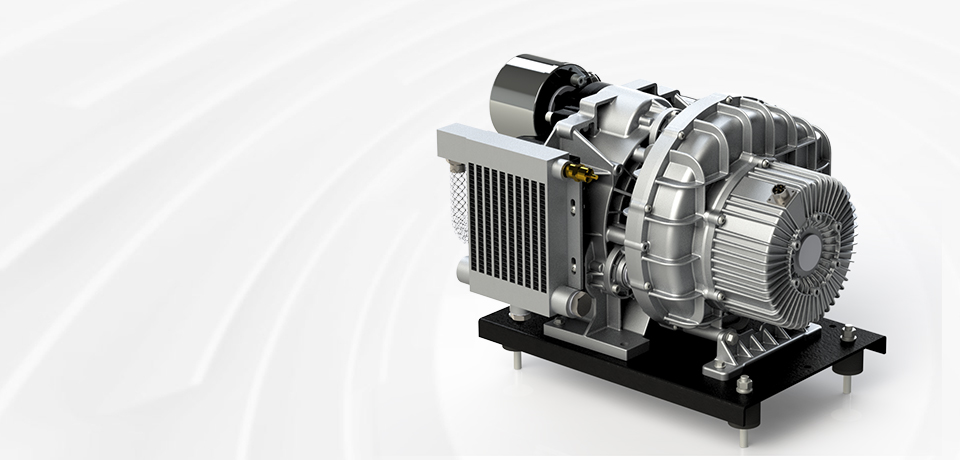

WORKING PRINCIPLE

——

Scroll air compressor is a new generation of air compressor developed in recent years. Compared with traditional air compressors, it has novel structure, small size, light weight, low noise, long life, smooth and continuous gas transmission, and easy operation. , low maintenance costs and a series of excellent technical properties, it is praised by the industry as maintenance-free air compressor and new revolutionary air compressor. It is an ideal model for air compressors below 50HP.

The scroll air compressor is composed of two dynamic and stationary scrolls meshing with each other in a double function equation shape. During the suction, compression, and exhaust processes, the static disk is fixed on the frame, and the moving disk is driven by the eccentric shaft and controlled by the anti-rotation mechanism. It rotates in a plane with a small radius around the center of the base circle of the static disk. The gas is sucked into the periphery of the static plate through the air filter element. As the eccentric shaft rotates, the gas is gradually compressed in several crescent-shaped compression chambers combined by the moving and static plates, and then is continuously discharged from the axial hole in the central part of the static plate.

HIGH RELIABILITY

HIGH RELIABILITY

LOW NOISE

LOW NOISE

LOW ENERGY CONSUMPTION

LOW ENERGY CONSUMPTION

LOW MAINTENANCE COST

LOW MAINTENANCE COST

FEATURES OF

SCROLL AIR COMPRESSOR

1 High reliability

1) The scroll compressor has fewer main engine parts, which is 1/8 of the number of piston compressors. The large reduction in parts is a key factor in improving reliability;

2) The radius of gyration is small and the linear speed is only 2m/s, resulting in small wear, high mechanical efficiency and small vibration;

3) The scientifically controlled whole machine system ensures improved stability

2 Low Noise

1) Due to the absence of suction and exhaust valves and complex motion mechanisms, the knocking sound of the valve plate and the blasting sound of the air flow are eliminated, which drastically reduces the noise;

2) Suction and exhaust are continuous and stable, more than 6,000 times per minute, making the air flow pulsation very small;

3) A 20HP (15KW) scroll air compressor has only a noise of 62dBA, which allows it to be installed and used anywhere, saving a lot of installation costs and more in line with environmental protection requirements.

3 Low Energy Consumption

1) Because of the suction boosting effect and the lack of clearance volume, the volumetric efficiency of the scroll air compressor is as high as over 98%;

2) Because several working chambers are gradually compressed, the pressure difference between adjacent working chambers is very small, so there is naturally less leakage. A compression process is divided into several compressions, with high thermal efficiency;

3) There are no suction and exhaust valves, so the resistance loss of intake and exhaust is almost zero. There is no friction and wear of the moving mechanism and high mechanical efficiency. This is the main reason why the scroll compressor saves much more energy than other air compressors. For example: (a 20HP15KW) scroll air compressor works 6,000 hours a year, saving up to 18,000 yuan in electricity bills.

4 Low Maintenance Costs

1) Due to the absence of suction and exhaust valves and complex motion mechanisms, the knocking sound of the valve plate and the blasting sound of the air flow are eliminated, which drastically reduces the noise;

2) Suction and exhaust are continuous and stable, more than 6,000 times per minute, making the air flow pulsation very small;

3) A 20HP (15KW) scroll air compressor has only a noise of 62dBA, which allows it to be installed and used anywhere, saving a lot of installation costs and more in line with environmental protection requirements.

400-880-5687 / 138 5725 7465

400-880-5687 / 138 5725 7465